Oomatshini bokwenza umqulu owenziwe ngamazinki bayinto ebalulekileyo kwishishini lemveliso, ngakumbi kwimveliso yamacangci esinyithi asetyenziswa ukufulela, ukugquma, kunye nezinye izicelo zokwakha. Aba matshini badlala indima ebalulekileyo ekubumbeni amashiti esinyithi esicaba kwiprofayili eyahlukileyo, ukubonelela amandla, ukuqina, kunye nesibheno sobuhle kwimveliso yokugqibela. Makhe siphonononge ukubaluleka kunye nokusebenza koomatshini bokwenza amazinki ngokweenkcukacha.

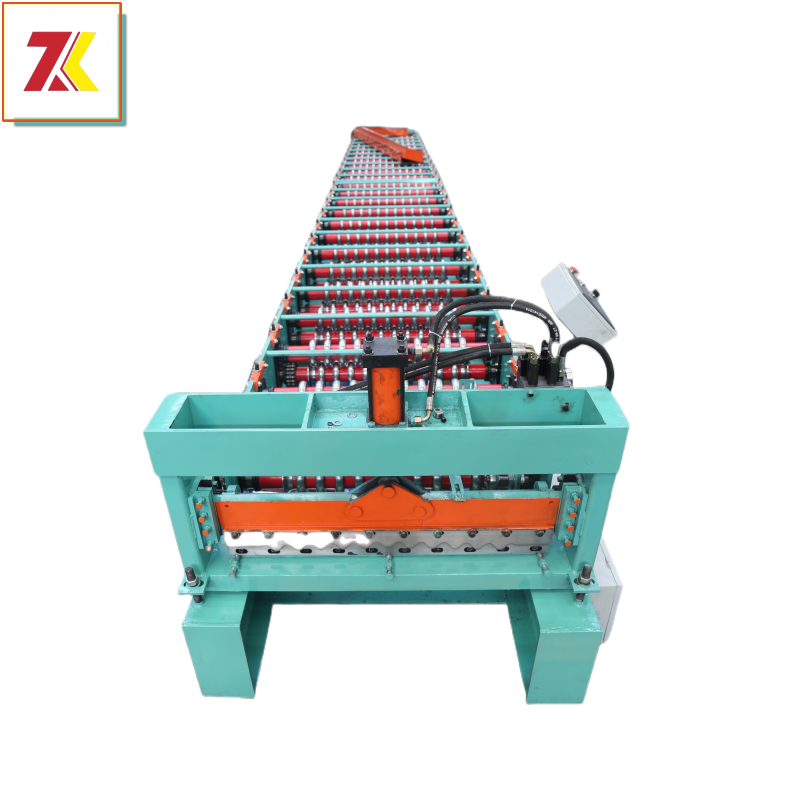

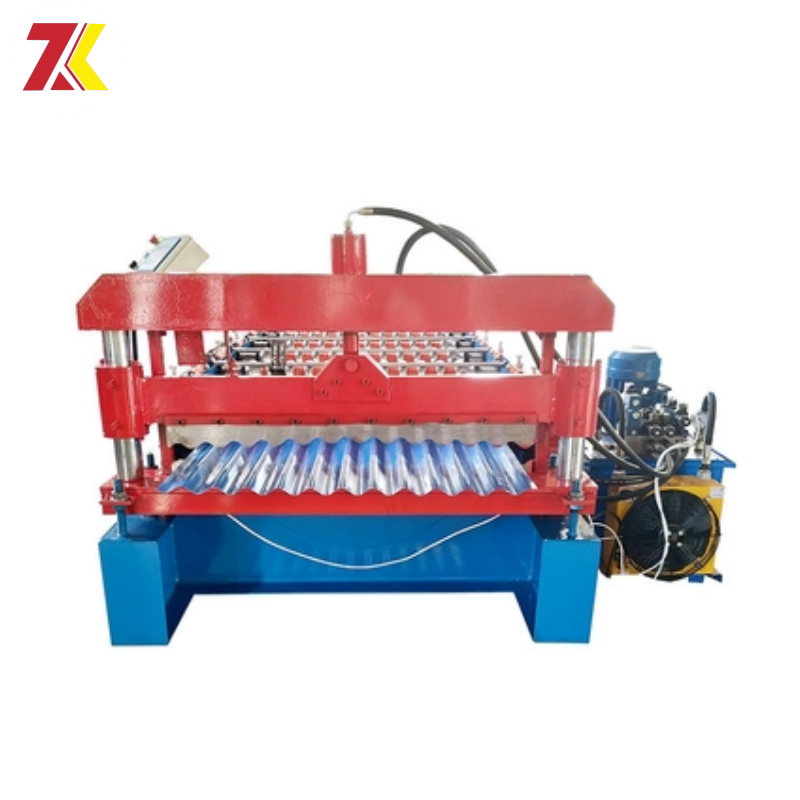

Umatshini wokwenza umqulu we-corrugated zixhobo ezikhethekileyo ezenzelwe ukuguqula iikhoyili zetsimbi ezisicaba okanye amashidi kwiiprofayili ezinqabileyo ngokulandelelana kwamanyathelo achanekileyo kunye nokulawulwa. Le nkqubo ibandakanya ukondla izinto zetsimbi ngokusebenzisa isethi yeerola ezibumba ngokuthe ngcembe kwaye ziyifake kwipatheni enqwenelekayo ye-corrugated. Uyilo oluntsonkothileyo nolobunjineli balo matshini luwenza akwazi ukuvelisa amashiti athathiweyo afanayo nakumgangatho ophezulu anemilinganiselo engaguqukiyo, eqinisekisa ukuba isiphelo semveliso siyahlangabezana nemigaqo efunekayo.

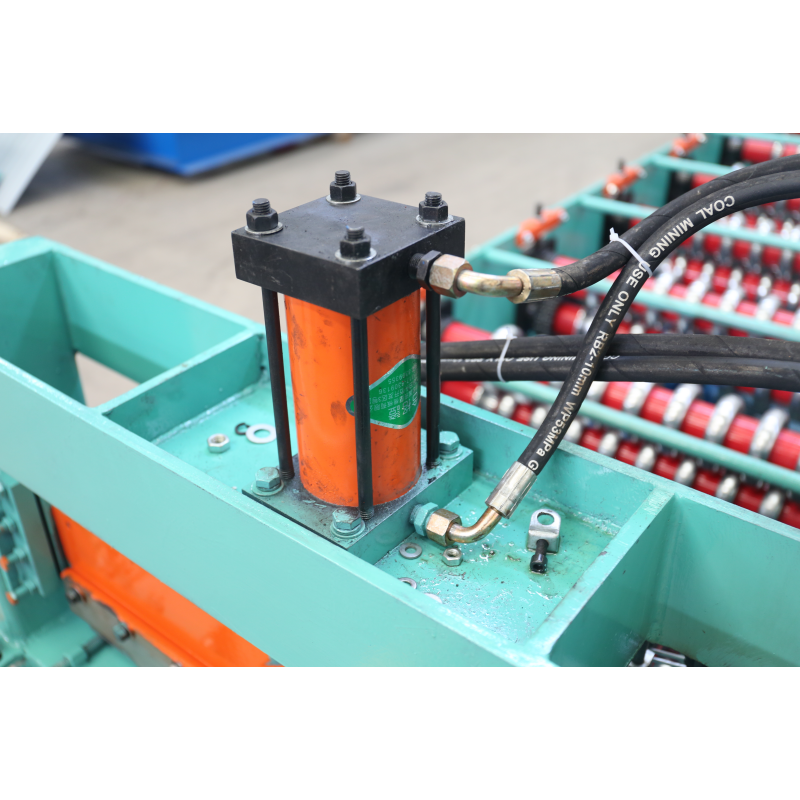

Enye yezinto eziphambili zomatshini wokwenza i-corrugated roll isethi ye-corrugating rollers, eyenziwe ngononophelo ukuze yenze amaza ahlukeneyo okanye ama-ridge kwiphepha lesinyithi. Ezi ziqengqelezi zilungelelaniswe ngokuchanekileyo kwaye zilungelelaniswe ukuze kuqinisekiswe ukubunjwa okuchanekileyo kweprofayili ye-corrugated, kwaye ziyakwazi ukulungelelanisa ukuvelisa iintlobo ezahlukeneyo zeepatheni ze-corrugation ukuze zihambelane nezicelo ezahlukeneyo. Ukongeza, umatshini ubandakanya iindlela zokusika kunye nokugqiba ukucheba amashiti athathiweyo ukuya kubude obufunwayo kwaye ulolonge imiphetho yolungelelwaniso olungenamthungo ngexesha lofakelo.

Ukuguquguquka koomatshini bokwenza amacangci kuvumela ukwenziwa koluhlu olubanzi lweemveliso zamalahle, kubandakanywa iipaneli zokufulela, ukugquma eludongeni, ukuhombisa, kunye nezinto zokubiya. Aba matshini bayakwazi ukusetyenzwa ngeentlobo ezahlukeneyo zesinyithi, njengentsimbi ekhandiweyo, i-aluminium, kunye nentsimbi engatyiwa, enika abavelisi ukuguquguquka kokuvelisa iimveliso zamathanki ezahlukeneyo ukuhlangabezana neemfuno zemarike.

Ukongeza kwizakhono zabo zokuvelisa, oomatshini bokwenza umqulu owenziwe ngamacangci benzelwe ukusebenza kakuhle kunye nemveliso. Ngokudityaniswa kolawulo oluphambili kunye neenkqubo ezizenzekelayo, aba matshini banokusebenza ngesantya esiphezulu ngelixa begcina ukuchaneka kunye nokuchaneka kuyo yonke inkqubo yokubumba. Oku akuphuculi kuphela imveliso yemveliso kodwa kukwaqinisekisa ukuba amacangci adibana nemigangatho engqongqo yobulunga.

Ngaphaya koko, oomatshini bokubumba amacangci benzelwe ukuthembeka kunye nokuqina, bevumela ukusebenza ngokuqhubekayo kwindawo yokuvelisa. Ukugcinwa okufanelekileyo kunye nokulungiswa rhoqo kubalulekile ukugcina ukusebenza komatshini kunye nokwandisa ubomi bawo bokusebenza. Ukongeza, abavelisi banokunyusa useto lomatshini kunye nolungelelwaniso lwezixhobo zokuziqhelanisa nobukhulu bezinto ezahlukeneyo kunye neeprofayili, ngakumbi ukomeleza ukuguquguquka kunye nokusebenza kakuhle.

Ukuqukumbela, oomatshini bokwenza umqulu owenziwe ngamacangci bayimpahla eyimfuneko ekuvelisweni kweemveliso zentsimbi, ezibonelela ngokudityaniswa kokuchaneka, ukusebenza kakuhle, kunye nokuguquguquka. Ngokukwazi kwabo ukuvelisa amacwecwe akumgangatho ophezulu kwizicelo ezahlukeneyo, aba matshini baluncedo ekuqhubeleni phambili ushishino lokwakha nolwemveliso, ukuhlangabezana neemfuno eziguquguqukayo zeziseko ezingundoqo kunye neeprojekthi zokwakha. Njengoko itekhnoloji kunye nokwenziwa kwezinto ezintsha kuqhubela phambili, oomatshini bokwenza amacangci baya kuhlala bephambili ekubumbeni ikamva lezinto zokwakha.

Ixesha lokuposa: Dec-26-2023